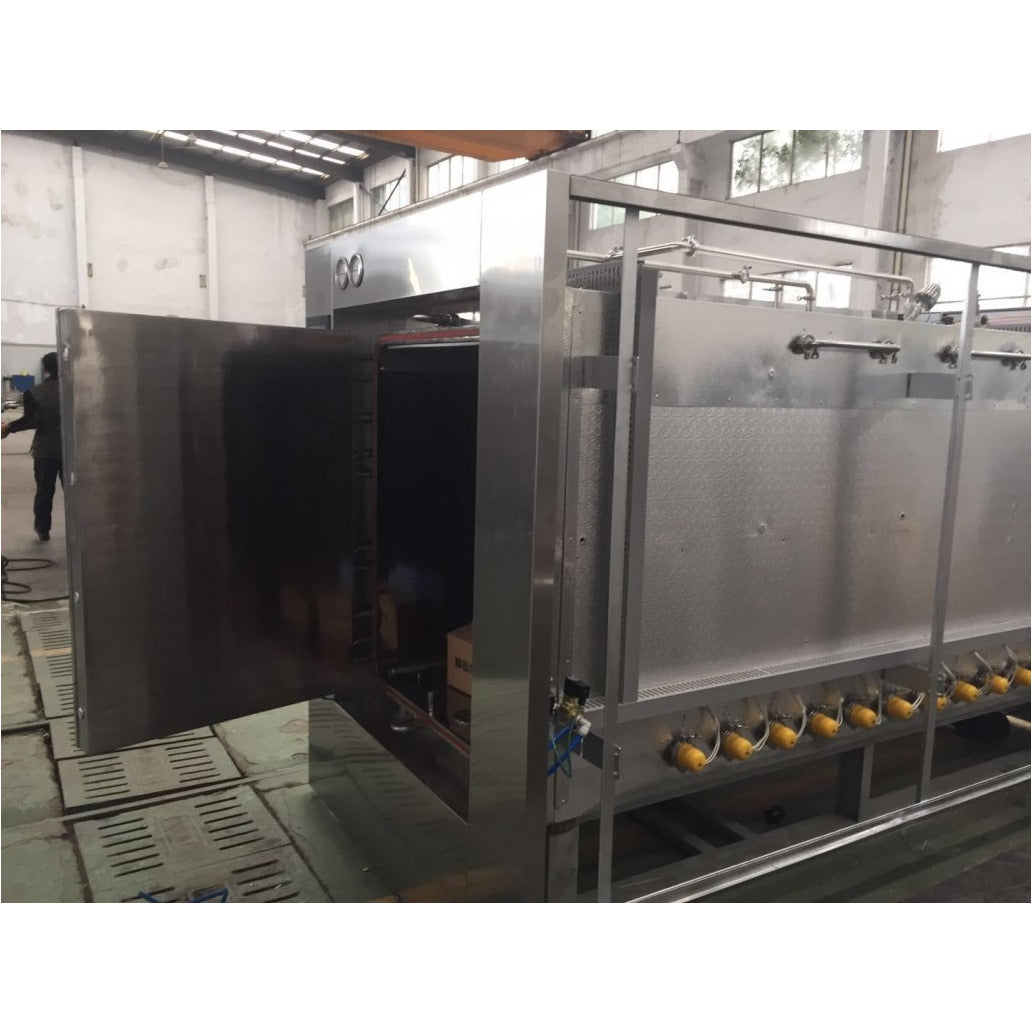

Water Spray Leakage Detection Ampoule Sterilizer For Vial

Water Spray Leakage Detection Ampoule Sterilizer For Vial

Model: SD-SG

General

This SG series adopts cyclical water as sterilization heating carrier and carry out water-pouring sterilizing operation for articles.

During the whole working course, superheated water operates in a relatively sealing cyclical system, which has series of advantages,high heat efficiency, good temperature evenness, stable temperature adjusting range, etc. Besides, this equipment also effectively prevents second pollution during working, with anti-pressure protection device. It can be applied widely to high-and-low temperature sterilizing operation on liquid in glass bottles, ampoule bottles, plastic bottles, plastic packs, etc, in pharmaceutics. Meanwhile, it is also suitable for foodstuff industry to sterilize all kinds of sealing package, drinks, cans.

According to adopting computers and high-performance devices, it increasingly improves the stability and intelligence of the machine, and makes it more suitable for high-intelligent management system of modern workshops. Meanwhile, refined manufacturing, world-famous configurations and good after service make you more satisfactory.

Documents

FAT, SAT, DQ, IQ, OQ, PQ.

Pipe System

Pipe system is consisted of internal circulation and external circulation. The former is sterilizing medium channel, mainly consisted of circulating pump, board type heat exchanger and internal spray system. The latter is “heating” and “cooling” supply channel, consisted of board type heat exchanger

-a- Pipe connection: connected by flange, the material is SUS304/316L

-b- Board type heat exchanger: The producer of the exchanger is ALFALAVAL Sweden which has large quantity of users and good service. It made by 316L stainless steel which is special design for high temperature working condition with high heat efficiency, easy to change the plates, easy clean.

-c- Circulating pump: The producer of the circulated pump is GRANDFOSS Denmark, which working temperature can over 150 ℃. The product is vertical multistage centrifugal pump, which is in low noise, low energy cost, free-maintenance and no leakage. This type product is widely used by national customers and after service net is quite complete.

-d- Spray system: The spray nozzle is produced by Spray Company, USA, and works in big water flux and wide spray angle. A lot of this type spray distributed in the top and side of the chamber can spray the high temperature water into water fog to every corner of the sterilization chamber. It assures the uniformity of the temperature and rapidly cool down the sterilization chamber and materials when needed.

-e- Control valves: The valves are produced by GEMU Company, Germany. The pneumatic water proof hammer angle valve is fixed in cooling water system that the system can work more smoothly. Other valves are heat resistance angle pneumatic valve which are special for steam (180℃). They are bid directional self-adjustable airproof, big flux with 6 million times working life.

-f- Steam trap: Steam trap is the key to control the steam consumption of super water sterilizer which is float-ball type produced by Spirax. sarco Company, UK. It is good at dividing water from steam with long working life.

Control System

The control system incorporated with: PLC + HIM+ DCS. It can be operated automatically and handly.

-a- The PLC can work over 50 thousand hours without any break down.

-b- The touch screen is colorful and clearly. The PLC is made by Siemens. which is the first in the PLC field. Because of powerful dynamic function, diagram editing function, communication function and so on.

The PLC has three function of data recording, attaching U card. Even if the host computer is broken, the temperature and pressure data can be also recorded in the card.

Main Parameters

1. design pressure: 0.245Mpa

2. design temperature: 139℃

3. working pressure: 0~0.22Mpa

4. working temperature: 60~134℃

5. heat equilibrium: ≤±1℃

6. steam pressure: 0.4-0.6Mpa

7. tap water pressure: 0.2-0.3Mpa

8. compressed air pressure: 0.6-0.8Mpa

9. pure water pressure: 0.2-0.3Mpa

10. materical: SUS304/SUS316

SADA MEDICAL Quality Standards:

ISO 9001:2015 Quality Management Systems

EN ISO 13485:2016 Quality Management System - Medical Devices

CERTIFICATES:

SADA MEDICAL Workshop:

Video of SADA MEDICAL Autoclaves:

Catalog, Brothures and User Manual Please refer below Link:

https://www.sadamedical.com/pages/catalog-download

Sada Medical is a professional supplier of steam autoclaves, low temperature plasma autoclaves, ethylene oxide sterilizers, dry ovens, consumables, we have exported to all over the world with affordable prices.

If you're interested in our products, please feel free to contact us by Below Contact Form, looking foward to hearing from you soon.